Shijiazhuang Jianda High-Tech Chemical Co.Ltd

founded in 2008,

has passed ISO9001:2008 certification

and GB/T19001-2008.

We are one of the largest Molecular Sieve

and 4A zeolite manufacturers in China.

Our main products are green non-phosphorus detergent 4A zeolite,

4A zeolite used as PVC heat stabilizer,

molecular sieve series,

molecular sieve powder series,

activated molecular sieve powder series,

which are widely used in detergent,

PVC industry, petrochemical industry,

oil industry, oxygen-making industry,

refrigeration industry, insulating glass industry,

pharmaceuticals industry and other fields.

Wholeheartedly welcome domestic

and international friends to visit our factory!

Tel: 0086-0311-89921819

Website: www.jiandagaokehuagong.com

Detergent industry "12th Five-Year Plan

Detergent industry "12th Five-Year Plan

Source: wash Association

The detergent industry "12th Five-Year Plan guiding principle is: Deng Xiaoping Theory and" Three Represents "as guidance, comprehensively implement the scientific concept of development, adhere to the strategic restructuring of the industry as the way of accelerating the transformation of the development of the industrythe main direction, adhere to the scientific and technological progress and innovation as an important support to accelerate the transformation of the mode of development of the industry, protect and improve people's livelihood as a fundamental starting point and final goal to accelerate the transformation of the mode of development of the industry, adhere to the construction of resource-conserving, environment-friendly societyas to accelerate the development of the industry as an important focal point to improve the development of comprehensive, coordinated, sustainable, and detergent industry is sound and rapid development.

The continuous development of our country has entered the ranks of producing countries of the world detergent product form and product variety are increasingly rich, professional, functional, personalized products continue to emerge, the formation of personal care and cleaning supplies, home care and cleaning supplies, industrial and public facilities clean.goods, the three category system. The development of cleaning products has also led to the development of related raw materials, most of the domestic production of additives, surfactant species can meet the needs of the detergent industry. With the steady development of China's economy, the process of urbanization continues to accelerate, the detergent is bound to continue to maintain steady growth is expected to detergent manufacturing enterprises in the national scale in the next five years the total output value of the average annual growth rate of 12% to reach 2060 to 2015 billion.

Detergent industry in China the status quo

(a) the "Eleventh Five-Year Plan" implementation of the "Eleventh Five-Year", the detergent industry comprehensively implement the scientific concept of development, market demand, to rely on scientific and technological progress, focus ongood structural adjustment, improve the competitiveness of the industry, the ability to enhance the sustainable development of enterprises the main line, to maintain the momentum of sustained and rapid development, economic efficiency improved greatly, greatly improved the capability of independent innovation, energy saving achieved initial success in the industrial corecompetition significantly enhance the ability to maintain steady growth of the detergent production, average annual growth rate above 6%.

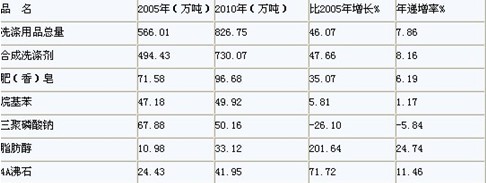

The detergent production in 2010 has reached 8.2675 million tons, of which 7.3007 million tons of synthetic detergent (synthetic detergent 3.9262 million tons), fertilizer (incense) Soap 966,800 tons, 499,200 tons of alkyl benzene, sodium tripolyphosphate 50.16million tons of fatty alcohols 331,200 tons, 4A zeolite 419,500 tons. From the 2010 data, the main products of the detergent industry has achieved the goal of "Eleventh Five-Year Plan".

Table 1, the "11th Five-Year Plan production targets for the implementation of

(B) of the detergent product output, production increased year by year

According to the latest statistics of the National Bureau of Statistics, our fertilizer (incense) soap and synthetic detergent manufacturing industry to create the industrial output value (current prices) in 2010 was 118.142 billion yuan, 112.526 billion yuan sales output value (current price). Detergent production was 8.2675 million tons in 2010, an increase of 5.15%. Among them, synthetic detergent, 7.3007 million tons, an increase of 4.60%; detergent 392.62 million tons, down 1.74%; fat (HKSAR) of soap 966.8 thousand tons, an increase of 9.46%. "Eleventh Five-Year" period, the average growth of output of main products of the detergent in more than 6%. Industrial output value of the average annual growth rate of more than 13%.

(C) the product structure has been optimized

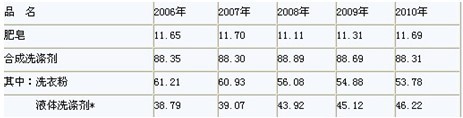

Table 2 lists the product mix changes from 2006 to 2010. Data from Table 2 can be seen, tended to optimize the product structure of the detergent industry, soap total steady growth, but the proportion decreased gradually; synthetic detergent production and the proportion is increasing year by year, in which liquid detergent production and the proportion of growth than fast, liquid washing products in 2010 accounted for more than 46% of the total amount of synthetic detergent products. Meanwhile, the strong momentum of development of industrial and public facilities, cleaning agent industry.

Table 22 006 years to 2010, China's detergent product mix changes (unit:%)

Note: liquid detergents, including dishwashing detergent, laundry detergent, hand sanitizer, and other household liquid detergent.

(D) regional industry development trend of significant

From the detergent production regional distribution, northeast area is relatively small, mainly concentrated in the East, Southern China area.In 2010 the detergent production more than 500000 tons of provinces and cities: Zhejiang, Anhui, Guangdong, Sichuan, Henan, total output is 5408700 tons, accounting for 65.42% of national output.

(e) the washing products market to enhance the degree of concentration

At present, washing products industry production concentration degree is higher, all varieties of major competitors of the relatively larger size.Is washing powder products, the 2010 nice, white, southerly, Procter & Gamble, Lonkey, white, Unilever, Chen, and, best of ten enterprises brand market share accounted for 86.95% of total.

(f) cleaning products quality is overall up-and-up

In recent five years, national quality inspection administration of washing powder, detergent and other products were repeatedly sampling.From table 3 shows the results of the sampling, five years apart liquid detergent for fabric product quality passing rate for 88.6%, other products quality qualified rate above 94.5%, indicating that the majority of enterprises to improve quality awareness, product quality and stability.

Table 32 005 2009 product sampling

Source: website of the State General Administration of Quality Supervision, Inspection and Quarantine of the sampling data

International overview of the detergent industry (a) the product structure in order to condensed, liquid-based the development of the detergent tends to be more focus on washing care effect, safe and convenient, environmental protection, conservation, packaging, simple and personalized needs and other aspects. At the same time, the United States and Japan are concentrated, liquid products mainly the European Union is actively promoting the enrichment process of the detergent. The latest data show that the ratio of the liquid laundry detergent has more than 80% of the total amount of laundry detergent; Japan concentrated detergent has accounted for more than 95% of the detergent market, and clothing accounted for using liquid detergent laundry products market share reached 40%; EU concentrated detergent share has more than 40%, the proportion of liquid detergent has reached more than 30%. Although liquid detergents have much room for development, global liquid detergent formulations still faces several major challenges. One of the challenges is typically used in the powdered detergent compatibility of good surfactants, additives and anti-redeposition agent incompatibility issues; The second challenge is that many of the surfactant in the presence of electrolytes, dissolved slower. To further improve the formulation, to improve the performance of liquid products, the global detergent industry in the positive efforts. The same time, the liquid detergent but also the use of plastic bottles, increased costs, countries are also committed to explore and try to reuse and reduce packaging

(B) chemical safety issues have become the focus of global attention

As people become more health conscious, on chemicals safety requirements getting higher and higher.The European Union in June 1, 2007 formally implemented "about chemicals registration, evaluation and authorization" (REACH code).In 2003 July, the UN officially approved the "chemical classification and identification of global unity system" (GHS), the provisions of the chemical hazards of global unified definition and classification, and the chemical labels and safety data exchange.At present, the Japanese have been devised for parts washing supplies (such as bleach, washing meal etc.) GHS management regulations, plan year began the trial.

In three, China cleaning products industry problems

Concentrated laundry detergent in China currently accounts for only about 4% of the total detergent, the vast majority are still on ordinary detergent based, contain more non-active chemical components is a waste of resources and increased consumption, affect product performance;soap by the influence of import prices of raw materials, fluctuations in raw material prices on the soap a great impact; products tends to be low-grade, over-reliance on price competition and expansion, not high value-added products; concentrated detergent of low-carbon economy, especiallyconcentrated liquid detergents accounted for a small proportion of the entire total detergent.

(B) low-price competition caused by difficulties in the development of enterprises

Price war after repeated washing industry end-product prices have been reduced to the basic bottom line, the entire industry into the era of meager profit. The low-price competition will only lead to inadequate investment in new product and technology development, market research, product promotion and other aspects of Over time, the detergent industry as well as the development of enterprises will inevitably be limited, the destruction of the industry value chain is not conducive to the industry healthy and sustainable development.

(C) the technological innovation capability needs to be further improved

Larger domestic enterprises gradually began to attach importance to investment in technological innovation, increase new technologies, new product development efforts, but the investment is still insufficient, the new achievements in the low rate of industrialization; new product output value accounted for the total output value of the low proportion of the marketsome of the special features of the raw materials is also dependent on the products of multinational companies. The lack of innovative capacity limits the ability of detergent industry continues to develop.

(D) of excess capacity, low-level redundant construction serious

According to industry surveys, the 2009 National detergent tower powder coating plant production capacity of more than 7 million tons, China's detergent production was only 3.93 million tons. The very existence of this phenomenon in the soap, oil and chemical industries, restricted the pace of structural adjustment of industry products, increased market competition in the industry, resulting in a serious waste of resources, and seriously affect the reasonable price and product quality stability.

(E) functional surfactant shortage

Our country produces the surfactant species to 40% species around the world.After the first few five year plan, China has achieved a large amount of localization of surfactant, can meet the basic needs of the industry, but still lack of high technology content, high product quality, cost-effective and special features of the novel surfactants.In 2010, China imported 310000 tons of surfactant, one hand shows the special function of the type of surfactant market demand, on the other hand, explained our country is part of the product is self-sufficient rate is low, the high degree of dependence on import

(6) energy-saving emission reduction task is arduous

Detergent industry, pressure on energy saving is reflected in two aspects: First, because the product structure is not reasonable and cleaning products to the ordinary powdered products based products effective matter content is low, a direct result of the production process and circulation, as well as spending isineffective energy consumption and material consumption, and adjustment of product structure is constrained by the technical level and variety of raw materials in production processes and equipment. Second, surfactant intermediates and products, technology and engineering level is not high, such as most of the production process are intermittent operation, the response of the power and thermal energy consumption is relatively high. Surfactant production areas of ecological and economic development contradictions are still prominent, and insufficient development of cleaner production processes, resource utilization efficiency and rationality need to be further improved, energy saving and emission reduction is not sufficient.

The basic idea of the 4, detergent industry "12th Five-Year Development

Detergent industry "12th Five Year Plan" national development strategies and industrial policies based on science and technology leading, innovation-driven, environmentally friendly, green-driven, market-driven, consumer-driven product energy, water, easy to rinse, efficient,multi-effect, the main line of environmental protection and security for the development of the industry, led to technological progress and innovation, speed up the adjustment of product structure, speed up the upgrading of industrial technology, and constantly improve people's quality of life, promote the sustainable development of the industry.

1, strengthen the construction of industry-standard system, focusing on product safety and to further improve the evaluation criteria, improve product quality, the protection of national life and health;

2, speed up the adjustment and optimization of product structure, vigorously develop and promote the enrichment and liquid washing products, to further promote energy conservation;

To strengthen the research and development and application of multi-functional, environmentally friendly surfactants and additives; the development of oil chemical industry, the development of oil chemical products and their derivatives, to improve take full advantage of renewable resources; to promote the transition to a green economy, the formation oflow consumption, recyclable, low emission, sustainable industrial structure, operation and consumption patterns;

4, technology upgrades, focus on product formulations and manufacturing processes to improve recycling, continuous level of automation and other aspects of starting, focusing on upgrading the raw materials and productsprocess technology and equipment levels, and promote clean production, enhancing the overall level of technology. ;

Five detergent industry "12th Five-Year" development of the key tasks

(A) to strengthen the industry standardization system

Focus on strengthening the improvement of the safety standards of products and raw materials, focusing on international and domestic product safety regulations and the industry-standard docking, strengthen product safety assessment methods and standards develop, strengthen the standard test method to study the formulation. Involved in environmental protection, human health indicators in the industry safety standards should be put forward higher requirements to meet today's living environment and quality of life growing demand and to promote awareness of the times of the detergent industry to provide consumers with safe products .

2, to further strengthen and improve the development of industry, cleaner production and energy conservation standards.

3, revision of existing product standards and raise the standard level, to strengthen the new standard-setting work of the concentrated product.

(B) to speed up the adjustment of product structure of the detergent industry

Energy, water, easy to rinse, efficient, multi-functional, environmental protection and security as a leading new product development. Great efforts to develop a variety of species, a variety of forms of energy and resources saving and concentrated washing products, reduce the use of Glauber's salt and other non-active ingredients, save resources, reduce the use of packaging materials, and further implementation of energy saving, and expand renewable resources and its derivatives in product usage and development of product line extension; detergent efforts to enhance product quality, accelerate the pace of development and application of new materials, new products, increase the value of the products. Enzyme preparation in detergent applied research, to promote the development of enzyme detergent products, biological enzyme, to replace some of the chemicals in order to reduce the use of chemicals and emissions. The positive development of industrial and public facilities, cleaning products, to increase R & D and product applications, and focus our attention on product safety improvement work.

(C) to accelerate the development of raw materials, applications, and promote the development of environmentally friendly, multi-functional raw materials, adhere to the road of sustainable technology

Focus on the development of functional environmentally friendly surfactant new varieties, to increase the development and application for non-phosphorus detergent, liquid detergent function of surfactant, concerned about the development and application of the surfactant has a special structure. Make full use of renewable resources, and focus on the development of oil chemical industry, the development of oil chemical products and their derivatives, to strengthen the functional and strong, biodegradable and good product development and application of the surfactant, to strengthen the renewable resources as raw materials research, development and application of surfactants. Further improve the study of detergent additives, the focus is to accelerate the development and application of liquid detergent additive as well as environmentally-friendly generation of phosphorus additives, to enhance research and development work as well as degradation of performance of environmentally friendly chelating agents water-soluble polymer things to help the development of research work of the lotion.

4, further strengthen the research and development of detergents with biological enzyme, to encourage more targeted function more effective, efficient enzyme preparation in detergents and other products. To establish the performance comparison of the surfactants and detergent, biodegradable active ingredients, toxicological analysis, environmental testing and impact assessment mechanisms and methods. To strengthen the Oil Chemical byproducts deep processing of applications.

(Four) from the the improve the recycling, continuous the level of automation and and other aspects of departure, focus on enhance the the the technical of products and raw materials the level of equipment, to promote clean production

A research and development of new continuous method of surfactant technology and equipment, the development of natural resources as raw materials, the surfactant-ton industrial technology, the development of the surfactant energy efficiency and cleaner production processes, engineering technology.

To strengthen the development and adaptation of manufacturing technology, highly efficient concentrated laundry detergent and liquid detergent production processes and equipment to carry out further studies and transformation; to accelerate the technological transformation of the traditional batch and backward technology.

(E) to promote the "three wastes", "zero emissions"

"Waste recycling and comprehensive utilization technology promotion, pay close attention to the elimination of backward production technology, technological transformation and introduction of advanced technologies, strengthen internal management, to prevent" leaking "waste and exhaust the full recovery use, developmentdownstream products, encourage enterprises to their own use of technology to study the recovery of the "three wastes", to find new uses for the "three wastes" of waste into good, turning waste into treasure.

(F) actively the establishment of the Japanese chemical industry, public technical service platform and technological innovation platform

Public technology platform and technological innovation platform, the platform should have the following functions: rational organization of basic research; raw materials, products and components, safety assessment, evaluation, thus ensuring the daily chemicals and its raw materials on the environment andecological security; development of advanced technical level of new products, detergents, surfactants and corresponding new technologies, enhance the industry's capability of independent innovation; to improve the existing standard system added, forming a perfect standard system; various research institutionstertiary institutions, scientific research to promote convergence, to achieve production, learning and research "docking to provide service support for industry research, production and reserve. Give full play to the above platform, and promote process optimization and industrial upgrading, promote the industry to achieve sustainable development.

(Vii) continue to strengthen the quality and brand building

Enhanced product quality is the awareness of corporate life, "to promote the use of information technology means to achieve the product life cycle management, to enhance the level of quality management; strengthen industry self-regulation, and further improve the follow-up survey of the quality of the detergent industry quality, timely notification to the consumercondition and improve the quality and safety level of the industry.

Enterprise development is inseparable from the brand building, creating and maintaining brand and make it a brand name is an important systems engineering. For businesses, the brand not only material wealth, but also the essence of its corporate culture; For consumers, the brand means reputation, is a guarantee of quality and taste. Enterprises should pay attention through the adjustment of product structure, improve the market share of its branded products; through technological innovation, improve the technical content of the product value, and by the breakdown of consumer demand, production of marketable products, thereby enhancing consumer loyalty.

(8) to strengthen the development of qualified personnel

Science and technology are primary productive forces, and human resources are the primary resources. The industry needs skilled specialists advice, industry experts widely from business, scientific research institutes. Recruit the talent of their own needs is the key to an invincible position in fierce market competition. To this end, industries and enterprises to strengthen the comprehensive personnel training mechanism construction, increase investment in manpower training each year shall determine the training objectives and indicators. Specialized research institutes and universities of professional of our country in the surfactants and detergent research is relatively small, tertiary institutions can be recommended to provide more professional and cultivate the industry's need in specialized talent that.

(9) to strengthen the publicity of the scientific use of detergent to enhance the quality of life and health awareness

The majority of our residents, even if some city residents, mostly limited to the type of detergent in the home of three types: soap, washing powder, detergent, indicating that the domestic consumer awareness of the detergent still in relatively early stage. Therefore, the whole industry should actively take action to play all forces, strengthen the knowledge of the scientific use of the detergent outreach, and enhance the quality of life and health awareness.

And restrictions (10) to eliminate the backward products, production processes and capacity

Restrictions the following products and processes: sodium tripolyphosphate 50,000 tons / year production line, single gun powder coating technology and equipment building; alkylphenol ethoxylates (typical product of TX-10), dual-octadecanedimethyl ammonium chloride (D1821), branched-chain alkyl benzene sulfonate (ABS) use of the product.

Production process eliminated the following: fatty acids in the legal system tertiary amine process (fatty acid → nitrile → primary amine → tertiary amine); oleum sulfonation process; stirred tank ethoxylation process.

next:In the associations: Laundry both cleaning and environmental protection